3D PRINTING CAR PARTS

IS IT POSSIBLE TO 3D PRINT CAR PARTS… With the right 3D printer anyone can create custom car parts from dashboards to air intakes to wide-body fenders.

3D PRINTED DASH | 3D PRINTER SETUP | BEST 3D PRINTER FOR CAR | 3D SCANNING CAR PARTS

PARTS LIST

You can also find plenty of free pre-created 3d car parts here:

AND to find the BEST 3d filament for printing car parts use our filament selector tool:

3D PRINTED AUTOMOTIVE MODELS

BMW VENT GAUGE

First up is a cooling vent that also functions as a gauge holder. The model was made by J0Mueller and can be found on Thingiverse.

This model replaces the stock BMW e30 mid sized front dashboard air vent. You can add a turbo gauge or any other gauge for that matter. Multiple vent gauges can be printed

THE 3D MODEL IS A SIMPLE DESIGN THAT’S PERFECT FOR A FIRST PRINT

TIME TO PRINT: 4 HOURS

Note: Print speed depends on the 3d printer infill density, infill pattern, and print speed.

COLD AIR INTAKE

Next is a custom cold air intake inlet. Our BMW e30 has 4 headlights and this 3d printed part replaces one of the high-beam headlights.

TIME TO PRINT: 11 HOURS

The air intake inlet is then connected to the intake manifold. The model was made by Johnny379 and can be found here on Thingiverse as well.

DIGITAL DASHBOARD

The third item on the list is a 3d replica model of a BMW e30 dashboard insert.

The model looks to have been scanned and converted into a 3d file and cost us $30 from Tangent Innovation. This is the largest 3d printed car part we could print on our 11.8”x11.8”x12.6” Ender 3 print bed without splitting up the part.

TIME TO PRINT: 20 HOURS

Once completed we added an LCD touch screen and Raspberry Pi to the 3d printed dashboard. We plan to swap our DME ECU to a Speedunio that can interface with the Raspberry Pi to display different digital gauges.

BEST 3D FILAMENT FOR CAR PARTS

Most beginners start with PLA filament because it's easy to print with. However, PLA can’t withstand the weather or the hot sun or wet environments.

PLA will start to warp around 120 F. ABS will not melt or sag in direct sunlight. Therefore you’ll want to print car parts with ABS-based filament.

Note: The downside to ABS is that it's a little harder to print with, but with higher hot end, bed heat, and an enclosure you’ll have successful results.

There’s also PEGT which has some weather-resistant properties but is said to print more easily than ABS. However, some have mixed results depending on filament selection.

We tested our 3d printed PLA vs PETG vs ABS car parts and here’s the results:

PLA filament started to sag in sunlight after 30 minutes.

PETG filament had no change after more than 1 hour.

ABS filament had no change after more than 1 hour.

For PETG printer settings, Creality has good directions for beginners here.

For ABS settings check out our 3d printing results on a Creality Ender 3 Max Neo here.

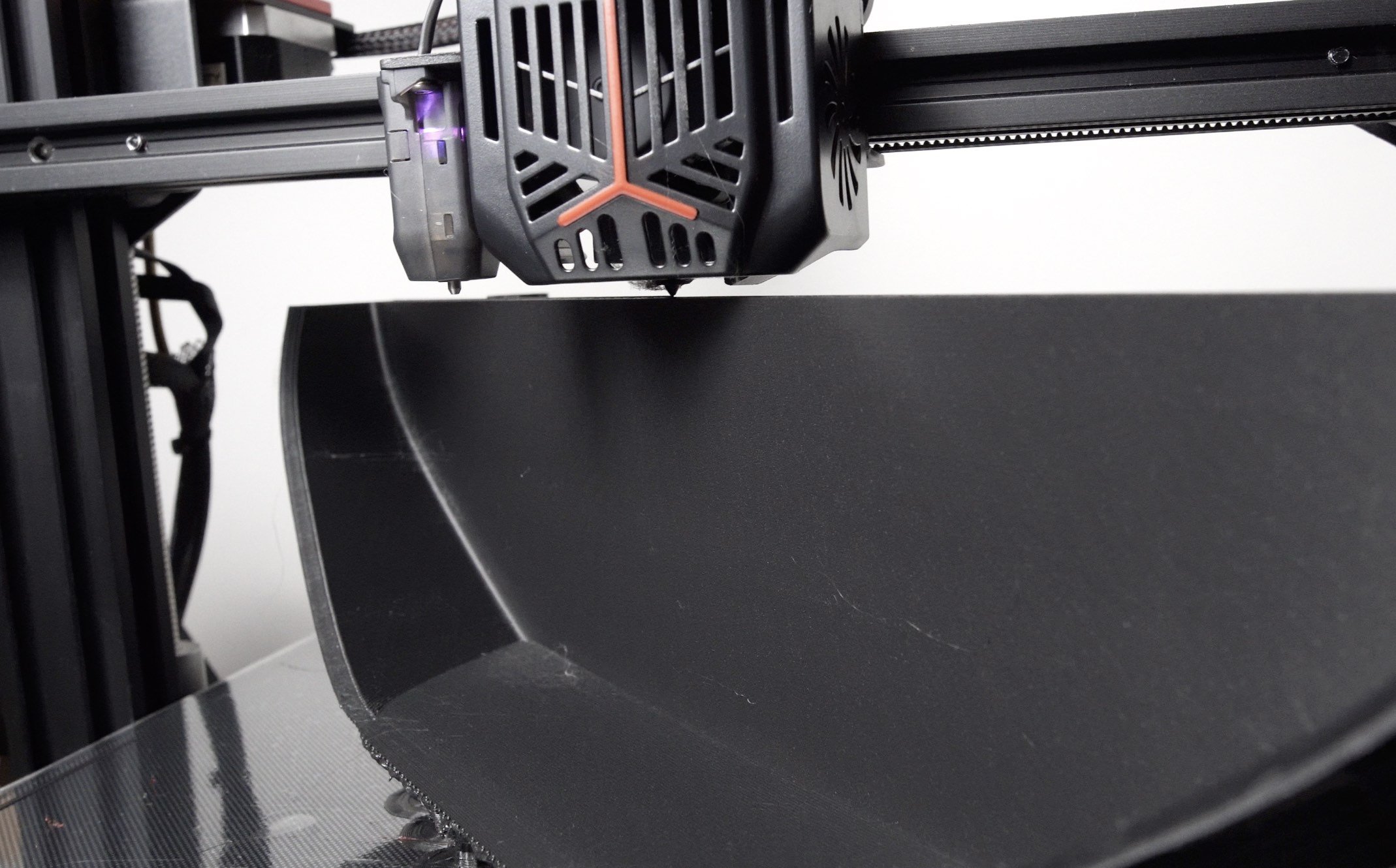

BEST 3D PRINTER FOR CAR PARTS

By far one of the easiest 3d printers to use with little to no fussing is any printer from Bambu Lab. The best bang for your buck will be the Bambu Lab P1S. Its print bed comes in at 10.07” x 10.07” x 10.07”.

Or you can check and see which Bambu Lab 3D printer is best for you…

LARGER 3D PRINTER BED SIZE?

If you want to print larger car parts like a full dashboard, then check out these other 3d printers:

Creality Ender 5 Max - 15.74”x15.74”x15.74” bed size

Creality CR-M4 3D Printer - 17.71” x 17.71” x 18.5” bed size.

Creality Ender 3 v3 Plus - 11.8” x 11.8” x 12.9” bed size.